centrifugal pumps Close Coupled and standardizeD EN 733

Centrifugal pumps close coupled (3D) cast iron.

APPLICATIONS- Water and clean liquids not chemically aggressive handling

- Water supply

- Pressure boosting

- Washing and industrial plants

- Water circulation in air-conditioning systems

- Irrigation and agriculture

- Highly resistant construction

- Impeller in stainless steel

- High efficiency

- Maximum working pressure: 10 bar

- Temperature of the liquid:

-5°C ÷ +90°C

-5°C ÷ +110°C (H-HS-HW-HSW versions)

-5°C ÷ +120°C (E version) - MEI > 0,4 for 3D(.) SERIES 2 poles, MEI > 0,1 for 3D(.) SERIES 4 poles

- High efficiency IE2 motors starting from 0,75kW

High efficiency IE3 motors starting from7,5kW up to 22kW - Self-ventilated 2 and 4 poles asynchronous motor

- Insulation class F (B for high temperatures)

- Protection degree IP 55

- 230V ±10% single phase voltage 50Hz,

230/400 ±10% (up to 4kW included) three phase 50Hz,

400/690V ±10% (from 5,5 kW and above) three phase 50Hz - Protection is user’s responsibility

- Pump casing in cast iron EN-GJL-250-EN 1561

- Impeller in:

- AISI 304 for 3D(.) SERIES 32, 40, 50

- AISI 316 microcasted for 3D(.) SERIES 65 - Shaft in AISI 304 (part in contact with the liquid)

- Mechanical seal in:

- Ceramic/Carbon/NBR (standard)

- Ceramic/Carbon/FPM (H version)

- SiC/SiC/FPM (HS version)

- Tungsten Carbide/Tungsten Carbide/FPM (HW version)

- SiC/Tungsten Carbide/FPM (HSW version)

- Ceramic/Carbon/EPDM (E version)

centrifugal pumps Close Coupled and standardizeD EN 73

Centrifugal pumps close coupled (3D) cast iron.

APPLICATIONS- Water and clean liquids not chemically aggressive handling

- Water supply

- Pressure boosting

- Washing and industrial plants

- Water circulation in air-conditioning systems

- Irrigation and agriculture

Centrifugal flanged electropumps, standardized

according to EN 733 and built in stainless steel AISI

304 (AISI 316)

- washing systems

- enological and food systems

- water treatment systems

- pumping of fluids reasonably aggressive

- conditioning systems

- heating systems

- pressure increase in industrial systems

- systems for air treatment/humidification

- Robust hydraulic construction

- Versatile, it is possible to handle a wide range of fluid

(304 or 316 version) - Volute casing for high efficiency

- With AISI 304 pump pump foot as standard

- All pump casing fixed screw in AISI 304

- Compact design

- Wide range of performances with 2-4 poles motor

- Standard dimension as ISO EN 733

- Back pull out design - easy to dismantle, pump casing

remain to the pipe

- Capacity up to 132 m3/h

- Head up to 72 m

- Maximum working pressure: 10 bar

- Temperature of the liquid: from -10°C to 90°C standard

-20° +110°C in H version

- Pump casing, impeller, casing cover and shaft in AISI 304

- Mechanical seal in carbon/standard/ceramic/NBR

- Mechanical seal version H in carbon/ceramic/Viton

- Mechanical seal version HS in SiC/SiC/FPM

- asynchronous motor 2 poles and 4 poles ventilated

- insulating class F

- protection degree IP55

- mono-phase voltage 230+/- 10%

- three-phase voltage 230+/400V +/-10% 50Hz till 4kW,

400/690V +/- 10% 50Hz for higher powers

- protection edited by the user

centrifugal pumps Close Coupled and standardizeD EN 733

Centrifugal pumps close coupled (3D) cast iron.

SINGLE IMPELLER CENTRIFUGAL ELECTRIC PUMPS

- Pressure boosting domestic plants

- Small-scale irrigation

- Moving non-aggressive liquids for civil and industrial use

- Washing plants

- Washing vehicles

- Available with brass impeller (CMA 0.50 M GO, CMA 0.75 M GO,

CMA 1.00 M GO) - The CMR version is equipped with an open impeller

- They can be inserted into machinery for industrial use

- Maximum working pressure:

- 6 bar for CMA 0.50 - 0.75 - 1.00, CMB 0.75 - 1.00 - 1.50 - 2.00 -

3.00, CMC , CMD , CMR

- 8 bar for CMA 1.50 - 2.00 - 3.00, CMB 4.00 - 5.50 - Maximum temperature of the liquid:

- 40°C for CMA 0.50 - 0.75 - 1.00

- 90°C for the rest of the range - G1 suction connection for CMA 0.50 - 0.75 - 1.00,

G1¼ for CMA 1.50 - 2.00 - 3.00,G2 for CMB - CMC,

G2½ for CMD - G1 discharge connection for CMA, G1¼ for CMB, G1½ for CMR,

G2 for CMC, G2½ for CMD

MEI>0,4 (CMA-CMC), MEI>0,1 (CMB-CMD) For further information

please see our Data Book

- High efficiency motors IE2 starting from 0,75kW

- Self-ventilated 2 pole asynchronous motor

- Class of insulation F

- IP44 Protection degree

- 230V ±10%, 50Hz single phase voltage,

230/400V ±10%, 50Hz three phase voltage - Permanent capacitor inserted and thermo-amperometric protection with automatic rearm incorporated for the single phase motor

- Protection under user's responsibility for the three phase version

- Cast iron pump casing

- Mechanical seal in Carbon/Ceramic/NBR

- Impeller:

- in PPE+PS reinforced with fibreglass for CMA 0.50 - 0.75 - 1.00

- in brass for CMA 1.50 - 2.00 - 3.00, CMB 2.00 - 3.00 - 4.00 - 5.50,

CMR 0.75-1.00

- in cast iron for CMB 0.75 - 1.00 - 1.50, CMC, CMD - Shaft:

- in AISI 416 (integral) for CMA 0.50

- in AISI 303 (part in contact with the liquid) for CMA CMA 0.75 -

1.00 - 1.50 - 2.00 - 3.00, CMB 0.75 - 1.00, 1.50 - 2.00 - 3.00, CMC

0.75 - 1.00

CMD 1.50 - 2.00 - 3.00, CMR 0.75-1.00

- in AISI 304 (part in contact with the liquid) for CMB 4.00 - 5.50,

CMD 4.00 - Bracket:

- in aluminium for CMA 0.50 - 0.75 - 1.00, CMB 0.75 - 1.00,

CMC 0.75 - 1.00, CMR 0.75-1.00

- in cast iron for the rest of the range

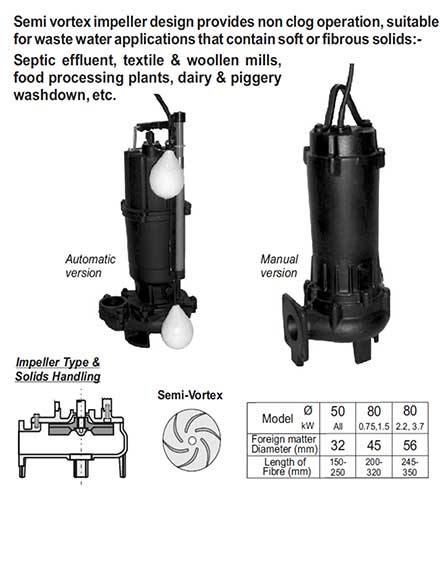

Applications

Ideal for waste water applications containing soft or fibrous solids.

Industrial waste water drainage

Septic effluent.

Miscellaneous drainage

- No clogging with semi-vortex construction

- Semi-vortex impeller offers non-clog operation and allows pumping of foreign particle

- Built-in motor protection

- Double mechanical seal

- DVSA model permits automatic operation

- Parallel alternate operation possible with DVSA and DVSJ models

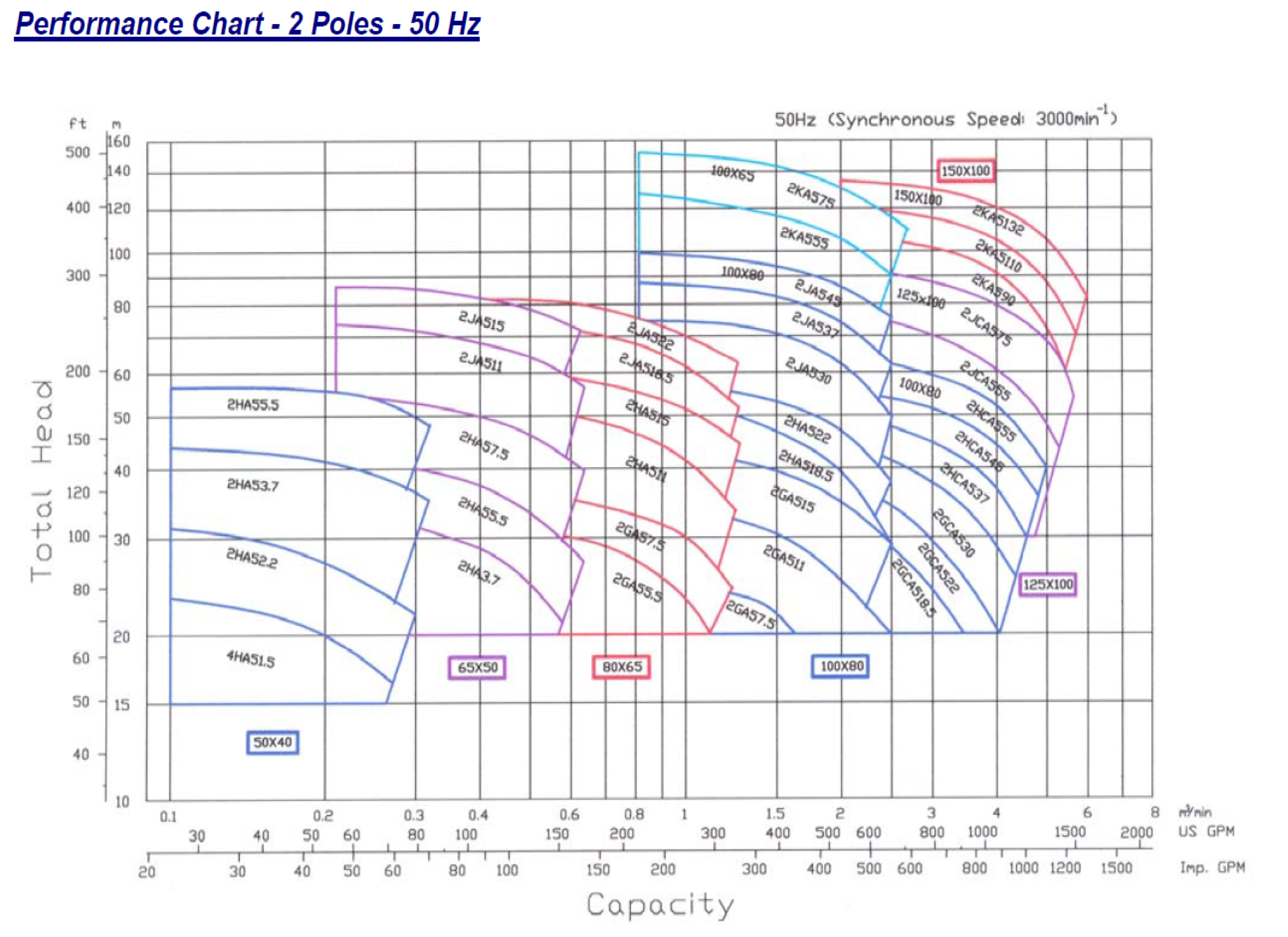

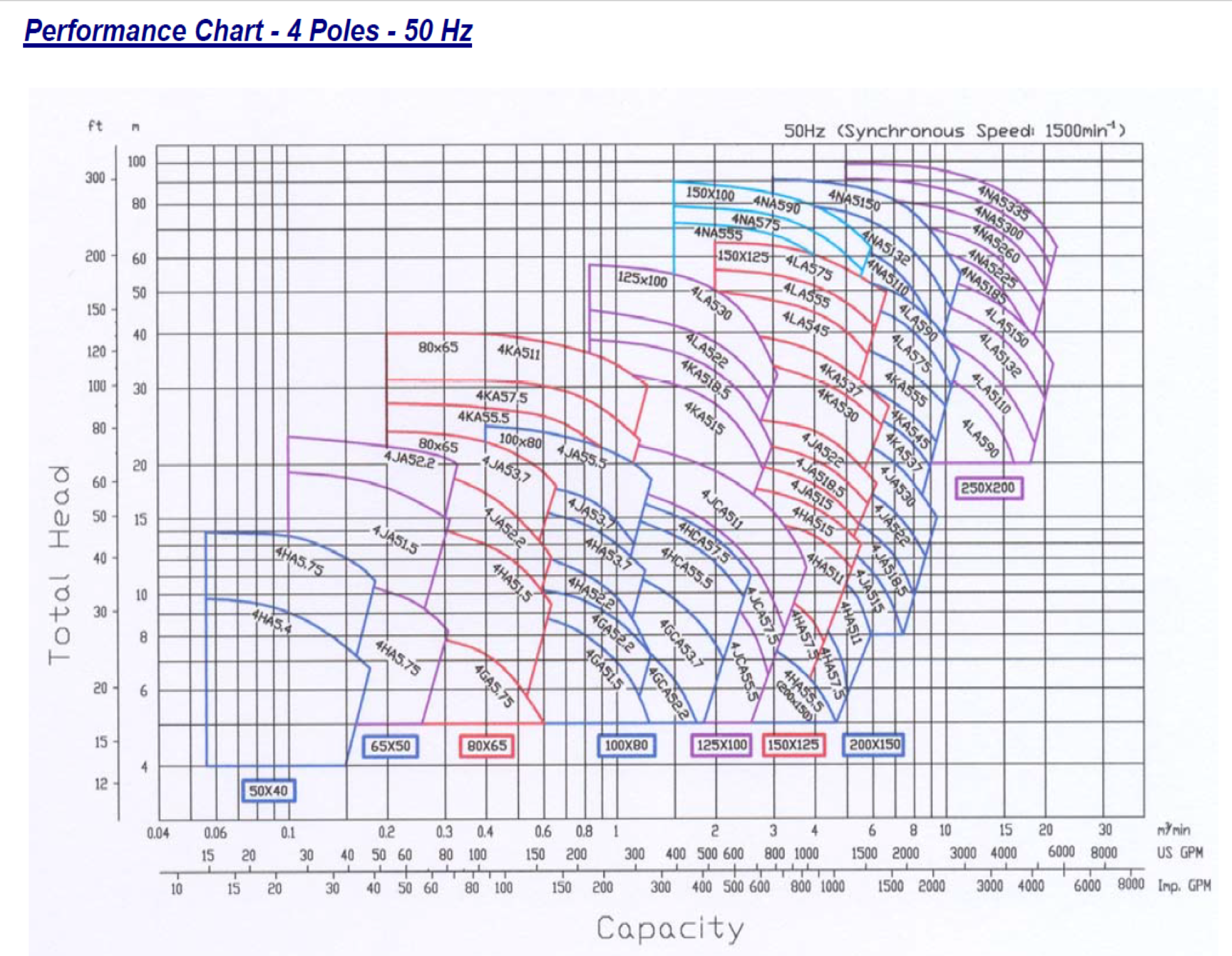

EBARA END SUCTION VOLUTE PUMPS

APPLICATIONS- Industrial use

- Water supply

- Hot and cold water circulation

- For swimming pool

- Sprinkling

- Air-conditioning

- Fire-fighting application

- Easy removal and maintenance, BPO (Back Pull Out) system allows all rotating element to be removed without disconnecting suction and discharge pipe work

- Top centreline discharge, foot support under casing for maximum resistance to misalignment and distortion from pipe loads

- Non-overload design to ensure stable performance for all applications

- Wide range application with flow capacity up to 22 m3/min

- Higher working pressure up to 16 bar